Not just child’s play: How India’s toy industry quietly became a global exporter

Discover how India’s toy industry is rapidly expanding its global export footprint. Backed by policy support, innovation, and rising demand, Indian toymakers are becoming global players.

Once overshadowed by cheap imports and struggling with low domestic output, India’s toy industry is undergoing a transformation. Over the past few years, India has quietly emerged as a significant player in the global toy manufacturing ecosystem. With rising exports, a supportive policy environment, and an increased focus on quality and innovation, the sector is no longer just child’s play—it’s serious business.

A Quiet Revolution in the Making

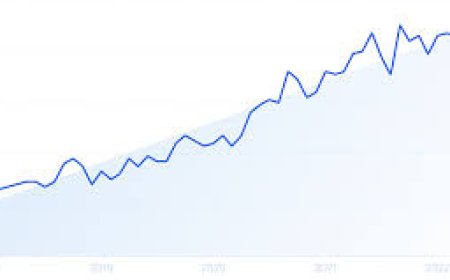

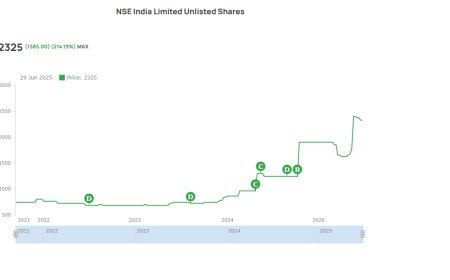

India’s toy industry, which was heavily dependent on imports (particularly from China), is now showing remarkable export growth. According to data from the Ministry of Commerce and Industry, India’s toy exports jumped by over 240% from ₹300 crore in FY15 to nearly ₹1,000 crore in FY24. The government’s Make in India push, tariff protections, and mandatory quality controls have played a pivotal role in this transformation.

“There’s been a structural shift. India’s toy manufacturing ecosystem has matured in quality, scale, and design. We’re now exporting to over 100 countries,” said Kumar Rajagopalan, CEO of Retailers Association of India.

Key Factors Driving Growth

1. Policy Support & Tariff Protection

The Indian government has raised import duties on toys from 20% to 60%, drastically curbing low-quality imports and giving local manufacturers breathing space. The introduction of mandatory BIS certification in 2020 has ensured improved quality and safety standards, aligning Indian toys with global benchmarks.

2. PLI Scheme & Cluster Development

The Production Linked Incentive (PLI) scheme for toys and focused development of toy clusters in states like Karnataka, Uttar Pradesh, and Madhya Pradesh are enhancing productivity and logistics efficiencies.

“Toy clusters are emerging as innovation hubs. With improved infrastructure and plug-and-play facilities, it’s easier for manufacturers to scale and innovate,” said Pankaj Mohindroo, Chairman of India Cellular and Electronics Association (ICEA), which also tracks the toy industry.

3. Demand from Global Retailers

India is now supplying to major global retailers like Walmart, IKEA, and Hamleys, largely due to diversification strategies by global brands seeking to reduce over-dependence on China. Indian toy makers have seized the opportunity with value engineering, cost competitiveness, and compliance with global safety norms.

Spotlight: Indian Manufacturers Gaining Global Traction

Homegrown players like Funskool, Skillmatics, and Smartivity are not only exporting but also winning international awards for design and educational value.

-

Skillmatics, an ed-tech toy company, became the first Indian brand to sell in over 15,000 U.S. stores, including Target and Amazon.

-

Funskool, a veteran in the Indian toy space, exports to over 20 countries and manufactures for global brands like Hasbro.

“India’s toymakers are blending tradition and tech—wooden toys with augmented reality, for example. That’s our niche,” said Manan Khurma, founder of an educational toy startup based in Bengaluru.

Market Outlook & Growth Projections

According to IMARC Group, the Indian toy market was valued at US$ 1.5 billion in 2023 and is expected to reach US$ 3.2 billion by 2029, growing at a CAGR of 13%. On the global stage, India’s share is still small compared to China’s dominant 70% market hold, but it's expanding steadily.

“India can become a global alternative to China in the toy supply chain, especially in eco-friendly and educational toys,” noted Radhika Rao, Senior Economist at DBS Bank.

Investor Sentiment and Industry Challenges

The booming toy sector has also caught investor attention. Private equity and venture capital firms are now exploring bets in early-stage startups focused on STEM learning, eco-friendly toys, and digital-native brands.

However, challenges remain:

-

Limited R&D investment

-

Fragmented supply chain in unorganised segments

-

Skill gaps in precision manufacturing

Despite these hurdles, the outlook remains robust.

“If policy momentum and export growth continue, toy manufacturing can become a ₹25,000 crore industry by 2030,” predicted Sandeep Bhargava, Consumer Sector Analyst at Anand Rathi Securities.

Government’s Vision: Toyconomy on the Rise

To institutionalize this growth, the Indian government has established a National Toy Action Plan which focuses on:

-

Promoting traditional Indian toys

-

Supporting startups with design and IP incentives

-

Encouraging global sourcing from Indian players through events like India Toy Fair

The recent launch of Toycathon, a hackathon to crowdsource toy ideas based on Indian culture, further underlines the state’s seriousness.

More Than Just Playthings

India’s toy industry is no longer just crafting playthings for toddlers—it’s shaping a globally competitive, culturally rich, and innovation-driven sector. As supply chains pivot and consumer consciousness shifts towards educational, ethical, and engaging toys, India is poised to be a major exporter in this global arena.

For investors and stakeholders, it’s time to pay attention—not just to the bottom line, but to the building blocks of a vibrant and high-potential industry.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0